Vinay Air System

Established in the year 2009, we are leading manufacturers, suppliers and dealers of Industrial Blower, Industrial Axial Fans, Tube Axial Fan, Man Cooler Fans, Centrifugal Fans, Industrial Air Ventilator, Multi Cyclone Fans, Bag Filters and Industrial Chimneys in Pune, Chakan, Aurangabad, Nashik, Maharashtra, Bangalore, Chennai,Nepal,Dubai, Hyderabad from India.

Trusted by Industry Leaders Across India

Transform Your Industrial Environment

Our engineered air solutions solve complex industrial challenges, ensuring optimal performance with reduced operational costs.

Enhanced Energy Efficiency

Our systems are designed to deliver maximum output while consuming up to 45% less energy than conventional systems, dramatically reducing operational costs.

Superior Durability

Constructed with industrial-grade materials, our systems withstand harsh environments, reducing maintenance needs and extending operational lifespan.

Expert Technical Support

Our team of specialized engineers provides comprehensive support from installation through the entire lifecycle of your system.

Engineered Air Solutions for Every Industry

Discover our comprehensive range of precision-engineered air handling systems designed to meet the specific demands of your industry.

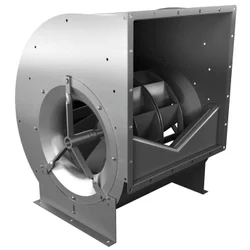

Industrial Blower

An industrial blower is a mechanical device used to move air or gases at high volume and moderate pressure. It is commonly used for ventilation, cooling, dust collection, drying, combustion air supply, and exhaust systems in factories and plants. Industrial blowers improve airflow efficiency, safety, and temperature control in industrial operations.

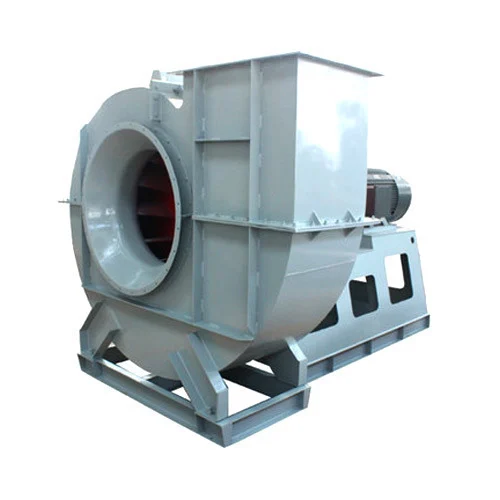

Centrifugal Blowers & Fans

Centrifugal Blowers are designed to deliver air at higher pressure and are used where air must overcome resistance (e.g., boilers, furnaces, dust collection, industrial processes).

Commercial Air Curtains

Air curtains create an invisible barrier of high-speed air across doors and entrances. They help keep indoor air clean and temperature-controlled by blocking dust, insects, fumes, and outside heat or cold. Widely used in shops, restaurants, malls, hospitals, and factories to save energy and improve hygiene.

Man Cooler

A Man Cooler is a large portable air cooler designed for outdoor or semi-open spaces like factories, warehouses, workshops, events, construction sites, and big halls.

Industrial Fans

Industrial Fans are heavy-duty air-movement machines designed for large spaces like factories, warehouses, workshops, power plants, and commercial buildings. Their main purpose is to circulate air, control temperature, remove heat, fumes, dust, and improve ventilation.

Bag Filter System

A Bag Filter System is an air pollution control device used to remove dust and fine particles from exhaust gases in industries. It works by passing dusty air through fabric filter bags, where dust gets trapped on the surface and clean air is released.

Spray Paint Booth

A Spray Paint Booth is a controlled enclosure used for applying paint or coatings safely and efficiently. It provides proper ventilation, filtered airflow, and dust control to ensure a smooth finish, reduce overspray, and protect workers from harmful fumes. Spray paint booths are widely used in automotive, industrial, furniture, and manufacturing applications to improve paint quality and comply with safety and environmental standards.

dust collectors

Dust collectors are systems used to capture, filter, and remove dust and fine particles from air in industrial and commercial environments. They help keep the workplace clean, protect machines, improve air quality, and ensure worker safety.

ID & FD Fan

These Fans are made of heavy duty construction with statically & dynamically balanced impellers which gives trouble free performance.Available air delivery 500 cum/hr to 1,50,000 cum/hr.These models consist of completely backward curved, backward curved with self cleaning and straight.

Trusted by Industry Leaders Across India

Hear from our clients about how Vinay Air System solutions have transformed their industrial operations and delivered measurable results.

Vinay Air System' fume extraction system transformed our production facility. Not only did it improve air quality dramatically, but we've seen a 32% reduction in energy costs. Their engineering team provided exceptional support throughout implementation."

Rajesh Sharma

Production Director, Tata Steel

"Implementing Vinay Air System' air curtain system at our facility entrances has significantly improved our climate control efficiency. We've reduced our HVAC costs by 28% while maintaining comfortable working conditions. Their technical support has been outstanding."

Priya Patel

Facility Manager, Sun Pharma

"The custom air washer solution from Vinay Air System has been a game-changer for our textile processing unit. The system not only maintains optimal humidity levels but has reduced airborne fiber content by 87%, significantly improving product quality and workplace conditions."

Vikram Singh

Operations Head, Arvind Mills

Making Your Decision Easier

We understand that investing in industrial air systems is a significant decision. Here's everything you need to know to make an informed choice.

How quickly will we see a return on investment?

Most of our clients achieve full ROI within 9-16 months, depending on the system and application. Our energy-efficient designs typically reduce operational costs by 30-45%, which accelerates the payback period. We provide detailed ROI projections during the consultation phase so you can see exactly when your system will pay for itself.

Will installation disrupt our operations?

We understand that downtime is costly. Our installation process is strategically planned to minimize disruption to your operations. Many systems can be installed in phases during planned maintenance periods or off-hours. Our experienced teams typically complete installations 30% faster than industry standards, and we provide detailed timelines before beginning work.

How do your systems compare to international brands?

Our systems meet or exceed international quality standards while offering several advantages: 1) Systems designed specifically for Indian industrial conditions, 2) 25-40% cost savings compared to imported systems, 3) Faster installation and commissioning, 4) Local technical support with response times under 24 hours, and 5) Readily available spare parts without import delays.

What maintenance requirements should we expect?

Our systems are designed for minimal maintenance with self-monitoring capabilities that alert you before issues arise. Typical maintenance includes regular filter changes and annual inspections. We offer comprehensive maintenance plans that reduce your involvement while extending system life. Many clients report 60% less maintenance time compared to previous systems.

Can your systems integrate with our existing infrastructure?

Absolutely. Our engineering team specializes in designing systems that integrate seamlessly with your existing infrastructure. We conduct comprehensive site assessments to understand your current setup and develop solutions that maximize compatibility while minimizing modification requirements. This approach reduces installation costs and implementation time.

What happens if our requirements change in the future?

Our systems are designed with scalability and adaptability in mind. We utilize modular components that can be reconfigured or expanded as your needs evolve. Many of our solutions include variable capacity controls that can adjust to changing requirements without hardware modifications. Additionally, our service agreements include regular reassessments to ensure your system continues to meet your evolving needs.

Still Have Questions?

Our engineering team is ready to address your specific concerns and provide detailed information about how our solutions can work for your facility.

The Vinay Air System Performance Guarantee

We stand behind every system we engineer, manufacture, and install with industry-leading guarantees that minimize your risk and ensure your complete satisfaction.

100% Satisfaction Guarantee

If you're not completely satisfied with your system within the first 90 days, we'll address your concerns immediately. we will resolve the issues to your satisfaction

Engineering Excellence Since 2009

For over 25 years, we've been at the forefront of industrial air handling innovation, delivering solutions that transform industrial environments across India.

Projects Completed

Enterprise Clients

Years Experience

Client Retention

Our Commitment to Excellence

Founded by experienced industrial engineers, Vinay Air System has grown from a small workshop to one of India's leading manufacturers of industrial air handling systems. An unwavering commitment to quality, innovation, and client satisfaction has defined our journey.

Engineering Excellence

Our team of specialized engineers combines decades of experience with cutting-edge technology to develop solutions that set industry standards for performance and efficiency.

Made in India, For India

We design our systems specifically for Indian industrial conditions, addressing unique challenges like varying power supply, extreme temperatures, and demanding operational environments.

Comprehensive Support

From initial consultation through installation, commissioning, and ongoing maintenance, we provide end-to-end support that ensures your systems perform optimally throughout their lifecycle.

Our Mission

"To transform industrial environments across India through innovative air handling solutions that enhance operational efficiency, workplace safety, and environmental sustainability."

Suresh Kumar

Founder & Managing Director

Our Quality Certifications

Our commitment to excellence is validated by rigorous industry certifications and compliance with international standards.

ISO 9001:2015

Quality Management System

ISO 14001:2015

Environmental Management

CE Certified

European Conformity

BIS Certified

Bureau of Indian Standards

Transform Your Industrial Environment

Take the first step toward optimizing your facility's air handling systems. Our engineering team is ready to create a tailored solution for your specific requirements.

Mr. Amarjit Chauhan (Proprietor)

+917040217760/ +919850517629

vinayairsystem.fan@gmail.com

Request a Consultation

Fill out the form below and our engineering team will contact you within 24 hours to discuss your requirements.

By submitting this form, you agree to our Terms of Service and Privacy Policy.

OUR GALLERY